Editor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Thoughts on accessibility and automation

How automation can allow for greater diversity

- By Rob Colman

- March 15, 2024

The week before we were set to complete this issue of Canadian Fabricating & Welding, I slipped and broke my wrist while out for a walk. Beyond the initial frustration of feeling like I should have known better than to be ill-prepared for the weather conditions, I didn’t give much thought to adapting to having the full use of only one arm, if only for the short term.

Most of us inevitably take for granted whatever mobility and fine motor skills we’ve been lucky enough to possess. Loss of those skills can be gradual or sudden, and society’s ability to accommodate those new needs isn’t always as it should be. Consider the struggle for wheelchair accessibility at many venues as the most obvious example. Although most publicly owned venues are now wheelchair accessible, many private businesses such as restaurants lag in adapting to such needs.

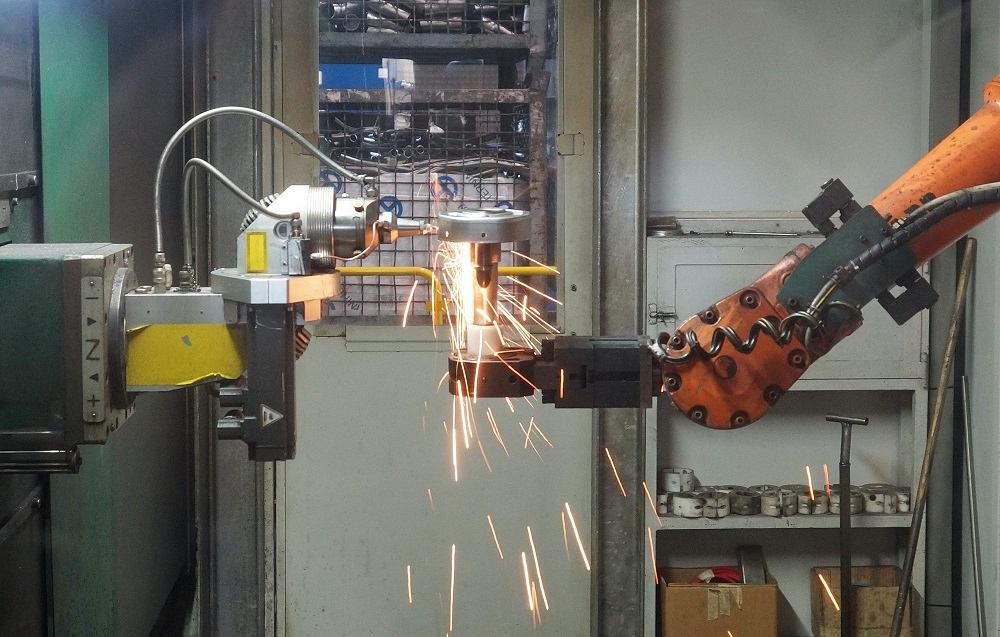

While discussing cobots used for welding and finishing with a number of experts this past month, it occurred to me how automation in all its forms can help a business adapt to not only productivity challenges but also the needs and abilities of its staff. For instance, an older manual welder may not be as fast or accurate as they once were, or they may just not want to be under the hood laying a bead anymore. But given a cobot to run, perhaps that welder could be encouraged to hold off retirement and support their team with the knowledge they’ve accrued.

Similarly, if you’ve got a robot that handles pick-and-place work or repetitive grinding jobs, perhaps an employee who previously experienced a repetitive strain injury could be assigned to these tools to complete tasks they’ve mastered manually without further exacerbating previous injuries.

All of these are steps to creating a more inclusive work environment as well. With the right tools, there’s less chance you’ll miss out on the latent talent of more people.

The inevitable question is, did I use voice recognition software to write this? Honestly, no, just my go-to hunt-and-peck method. But it was nice to be reminded by a colleague that this was a legitimate option available to me if I needed it. That’s all anyone wants—a legitimate route to prove their abilities.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free SubscriptionAbout the Author

Rob Colman

1154 Warden Avenue

Toronto, M1R 0A1 Canada

905-235-0471

Robert Colman has worked as a writer and editor for more than 25 years, covering the needs of a variety of trades. He has been dedicated to the metalworking industry for the past 13 years, serving as editor for Metalworking Production & Purchasing (MP&P) and, since January 2016, the editor of Canadian Fabricating & Welding. He graduated with a B.A. degree from McGill University and a Master’s degree from UBC.

- Trending Articles

Aluminum MIG welding wire upgraded with a proprietary and patented surface treatment technology

Achieving success with mechanized plasma cutting

Hypertherm Associates partners with Rapyuta Robotics

Brushless copper tubing cutter adjusts to ODs up to 2-1/8 in.

Gema welcomes controller

- Industry Events

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI