Technical Advisor

- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Digital assets help shops organize

ISO 13399 standardizes cutting tool data when ordering tools

- By Andrei Petrilin

- July 11, 2022

- Article

- Cutting Tools

A supplier’s catalogue often is the best source for becoming acquainted with its products. The term catalogue even derives from the ancient Greek word for list.

Originally, a product catalogue was a printed document listing all the products a company offered. Later, catalogues began incorporating reference data, general recommendations for using products, and additional related technical information. In cutting tool manufacturing, these supplements presented the initial cutting conditions, accessories, mounting and regrinding instructions, troubleshooting, and technical information.

As computing technologies evolved, electronic versions of these hard-copy catalogues, with significantly expanded capabilities like search options, became popular. Now, user-friendly e-catalogues facilitate optimized product searches and include filtering functions, visual assets, and reference data.

The cutting tool industry has kept pace and, indeed, “soft” digital product data formats now dominate the traditional “hard” printed materials. The digital era concept of smart, data-driven manufacturing prioritizes digital information.

Going Digital

Today conventional paper catalogues only provide the key dimensions of a cutting tool, an indexable insert, a toolholder, or spare parts and, consequently, do not offer enough information.

More intensive data transfer and the rapid pace of digital-era processes are inevitably leading to substantially increased unified data representation when building digital information for the metalworking industry. An important step in unifying the digital information related to cutting tools and toolholders is the ISO 13399 standard.

ISO 13399 is a set of international standards enabling multiple tool manufacturers to use the same terms to reference their products—a single set of common identifiers designed to make it easier for software platforms such as CAM systems and simulation tools to work together.

Following the guidelines of this standard helps ensure data uniformity, makes the digital twins understandable for real and virtual components of manufacturing systems, and supports real-time information exchange between the components. An ISO 13399-compatible computer-aided engineering (CAE) system downloads tool data directly from the cloud to provide information instantaneously. Therefore, meeting the requirements of ISO 13399 is a key feature of an effective cutting tool e-catalogue.

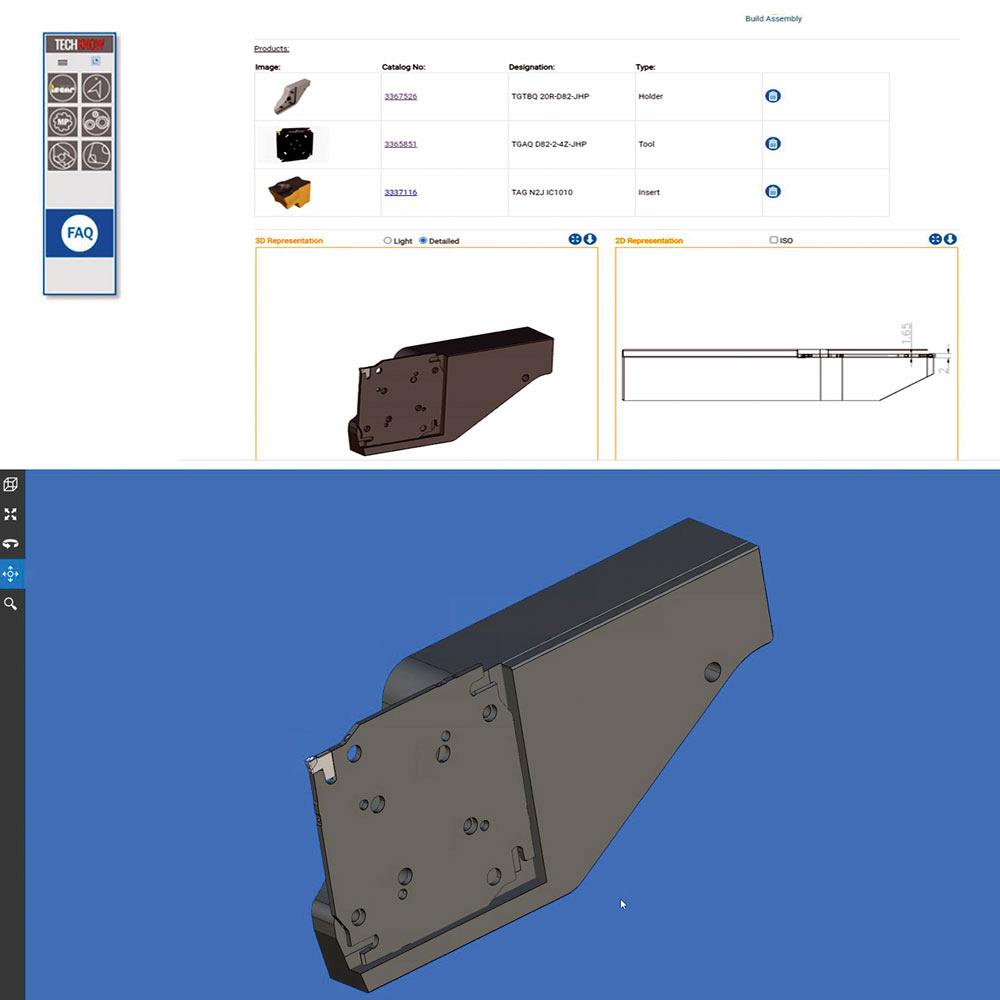

E-catalogues also should have built-in functions that facilitate the effective processing and filtering of information to meet the customer’s needs for building and ordering tools and tool assemblies.

A virtual tool assembly comprises the cutting tool, indexable inserts or exchangeable cutting heads, a toolholder, extensions, and reducers, which help with pre-machining, anti-collision planning. The digital version of the tool assembly, created from an e-catalogue, can be downloaded into the CAE system for virtual machining simulations to optimize cutting strategy, collision checking, improving tool configuration, and other procedures for technological machining processes.

ISCAR's e-catalogue, for example, links to the new ISCAR tool advisor (NEOITA), which recommends the best tools for a given application. Alongside this app is the Machining Power Calculator that estimates power consumption and cutting forces during machining, Productive Geometries for finding inserts of alternative cutting geometry, Grade Optimizer for finding equivalent cutting material grades, and the FAQ section.

E-catalogues also connect with data sources to ensure optimal tool selection and offer access to e-commerce functions. This makes the e-catalogue an inseparable subsystem embedded in a world of information technologies associated with cutting tool manufacturers.

Another undeniable advantage of e-catalogues, when compared to the traditional paper ones, is the ease of maintenance. Changes and updates can be made online instantaneously at any time.

Going Mobile

Because of the progress in mobile phone technologies, cutting tool e-catalogues also have advanced to provide access to tool information anywhere virtually.

By using the e-catalogue, customers can receive an STP file independently with a .p21 extension that meets the requirements of ISO 13399 standard to transfer data for CAE systems. This helps make cutting tool e-catalogues an effective and diversified source of vital information and creative possibilities.

Will the e-catalogue ever totally replace the paper catalogue, though? Printed catalogues remain in demand because many customers still are avid users of the provided information, which does not rely on internet infrastructures. This means that cutting tool manufacturers will continue to provide both digital and printed catalogue versions for the foreseeable future.

However, there is no doubt that the digitization of the metalworking industry will bring e-catalogue use to the forefront, providing additional functional value for metalworking shops.

Andrei Petrilin is technical manager for ISCAR Tools, 2100 Bristol Circle, Oakville, Ont. L6H 5R3, 905-829-9000, www.iscar.ca.

About the Author

Andrei Petrilin

2100 Bristol Circle

Oakville, L6H 5R3 Canada

905-829-9000

Related Companies

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Industry Events

Automate 2024

- May 6 - 9, 2024

- Chicago, IL

ANCA Open House

- May 7 - 8, 2024

- Wixom, MI

17th annual Joint Open House

- May 8 - 9, 2024

- Oakville and Mississauga, ON Canada

MME Saskatoon

- May 28, 2024

- Saskatoon, SK Canada

CME's Health & Safety Symposium for Manufacturers

- May 29, 2024

- Mississauga, ON Canada